Technology is transforming nearly every industry, and construction is no exception. One form of tech that has recently had a substantial impact on the construction industry is three-dimensional (3D) modeling. 3D models have a major role in modern construction projects, as they can improve productivity and ease of work.

3D modeling for earthworks and machine control can increase equipment operation accuracy, enhance worksite efficiency and reduce costs, among other benefits. So, how does this technology work, and how can you apply it to your next project?

JUMP TO SECTION

Unraveling the Fundamentals of 3D Modeling

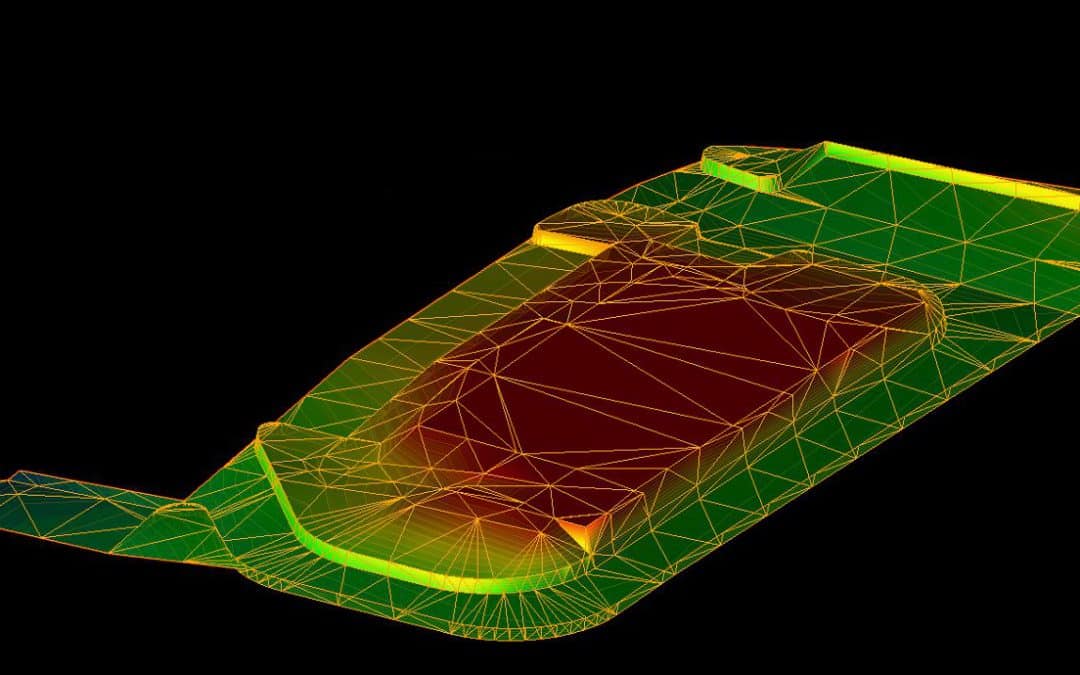

The term “3D modeling” refers to the process of creating a three-dimensional representation of an object using specialized software. This representation, called a 3D model, can convey an object’s size, shape and texture. You can create 3D models of existing items, as well as designs that have not yet been built in real life.

In construction, 3D models of a worksite can be used for machine control. These replicas incorporate the points, lines and surfaces that make up the physical environment. They use coordinate data that identifies the location of horizontal and vertical points relative to a reference point. Due to these spatial relationships, you can view the representation from various angles.

Machine control uses various positioning sensors to provide machine operators with feedback on things like target grades and bucket or blade position. The machine operators can reference the 3D model to ensure they are completing work accurately. GPS survey technology enables workers to locate the replica’s points in the field, and sensors on machines tell them where they are relative to the model’s points.

These control processes help crews translate the 3D model into reality by guiding equipment to construct the lines, points and surfaces precisely as described in the representation. Teams may also use 3D models for project, design and environmental compliance reviews. These models also help during pre-bidding, allowing contractors to test out various designs and communicate ideas.

Embark on Efficient Construction with Accurate 3D Models

With TOPS, get a glimpse into your construction project before it begins with our expert 3D models. Whether complex or straightforward, our models prepare data tailored to your needs, ensuring rapid work orders and enhanced project forethought.

Tracing the Evolution of 3D Modeling Techniques

The methods and technologies used today for 3D earthworks modeling would not exist without developments in civil surveying and various types of 3D modeling.

You can trace the history of 3D earthworks modeling back to ancient times. Ancient Egyptians constructed the pyramids with early surveying techniques and used geometry to re-establish farmland boundaries after flooding along the Nile River. In ancient Rome, civil surveying became a recognized profession, and surveyors created measurement systems to evaluate and create records of conquered lands.

Euclid, who is known as the founder of geometry and lived in ancient Greece, developed ideas that inspired many modern surveying and 3D modeling techniques. Many years later, in the 1600s, French mathematician Rene Descartes invented analytic geometry — also called coordinate geometry — which is foundational to 3D earthworks modeling.

Moving forward to the 18th century, European surveyors discovered they could use various angle measurements taken from different areas to identify a precise location — a technique known as triangulation. New surveying tools, such as measuring wheels, circumferentors, Kater’s compasses and Gunter’s chains, began to gain popularity. Meanwhile, English mathematicians James Joseph Sylvester and Arthur Cayley developed matrix mathematics, which is what enables today’s computer-generated images to display reflections or light distortions.

Later, surveyors began to use steel bands and invar tapes. These tools eventually gave way to technologies such as electromagnetic distance measurement (EDM) and global positioning satellite (GPS) equipment. Surveyors switched from compasses to theodolites, which measured horizontal and vertical angles using a rotating telescope. They then transitioned to using total stations, which are electronic transit theodolites equipped with EDM technology. These advancements enable them to measure both angles and distances.

Then, the first commercially available computer-aided design (CAD) systems — which turn survey data into visual representations — were released. The first 3D graphics company, Evans & Sutherland, appeared in 1968. Over the next several decades, CAD programs became more advanced and more widely available.

In the machine control field, users began shifting from the use of survey stakes — which surveyors manually set up, and machine operators read visually — to 3D modeling. Various technologies came together to enable 3D earthworks modeling, including:

- CAD, which turns survey data into a 3D model.

- GPS, which allows engineers to pinpoint precise locations.

- Light Detection and Ranging (LiDAR), a remote sensing technology that uses a pulsed laser to measure variable distances.

- Aerial photogrammetry, which enables engineers to extract topographical data from aerial photographs taken by drones.

- Point-cloud modeling, which involves using laser scanning technology to create a set of three-dimensional data points used to create a model.

Innovative Uses of 3D Models Across Industries

3D replicas are a prevalent form of technology, but what industries use 3D modeling? Many sectors use 3D modeling for numerous purposes. Some concepts include:

- Planning buildings using architectural visualization.

- Giving 3D tours in the real estate sector.

- Creating video games and movies.

- Conducting academic research.

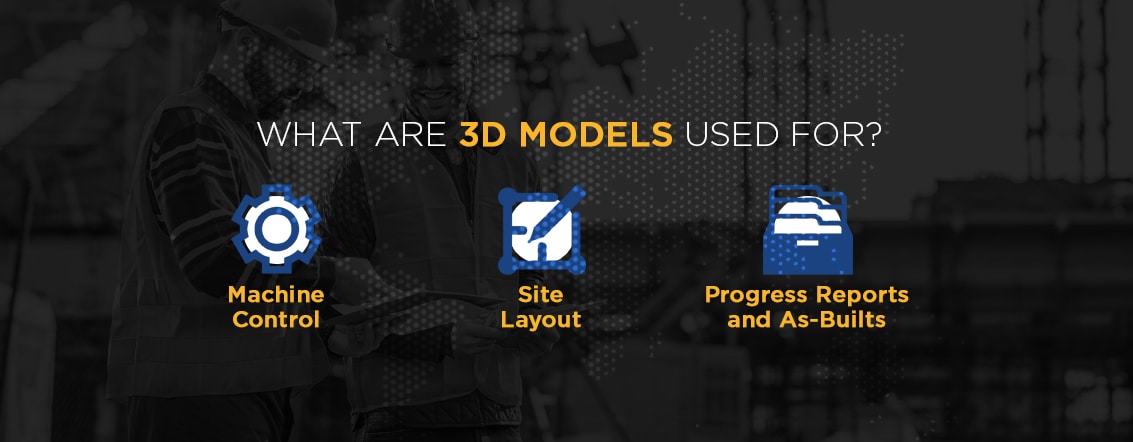

Models have several uses in construction as well, and new techniques are always emerging. Here are a few ways 3D models are used in construction:

Precision Machine Control Through 3D Modeling

3D modeling enables more accurate, efficient and cost-effective machine control. Instead of using traditional survey stakes, machine operators can see the job site on a screen while in the cab. A system of sensors guides the machine based on the 3D model’s measurements.

Equipment such as excavators, backhoes and bulldozers are equipped with on-board computers, and the blades and buckets include GPS devices. You can either set up a GPS base station at the worksite or subscribe to a GPS service. Whichever system type you choose, it will communicate with the receivers on your machines.

The 3D model is referenced to GPS coordinates and loaded onto your equipment’s on-board computers. These computers can then communicate with GPS receivers and machinery controls. As the device moves throughout the site, the GPS records where it is located at all times. As the blades and buckets on your machinery move, the GPS pinpoints their position.

The computer can automatically adjust the blades or buckets to the required excavation depths or surface elevations. This ability enables smooth, accurate grading of roads, sidewalks and parking lots and more.

Strategic Site Layout Planning with 3D Models

3D models can also be useful for communicating site layout, including the location of utility equipment and landscape elements.

You can map the location of electrical equipment, for example. That can include electrical service slabs, light poles and connections for signs, kiosks, decorations and other electrically powered elements. A 3D model helps electricians set these connections up quickly and accurately.

You can also use 3D mapping technology to map other utilities, including gutters, water and wastewater piping, natural gas lines and more. Charting the layout of utilities gives crews more confidence about their placement and provides them the information they need to place this equipment at any time.

A 3D model can also include elements such as landscaping, curbing, benches and nearly any other site feature. Accessories such as benches and playground equipment require a base and connection. Knowing where these elements will go can enable crews to prepare them earlier in the process and avoid re-digging later.

Enhancing Construction Reporting with 3D As-Builts

3D models can also be useful for communicating project progress and creating as-builts, which are revised drawings submitted at a project’s completion. You can gather new data throughout an assignment to create updated 3D models, showing what the site currently looks like. A 3D model created after a project ends can be used throughout the lifecycle of the facility for purposes such as maintenance, operations and asset management.

The Advantages of Implementing 3D Models in Earthworks Projects

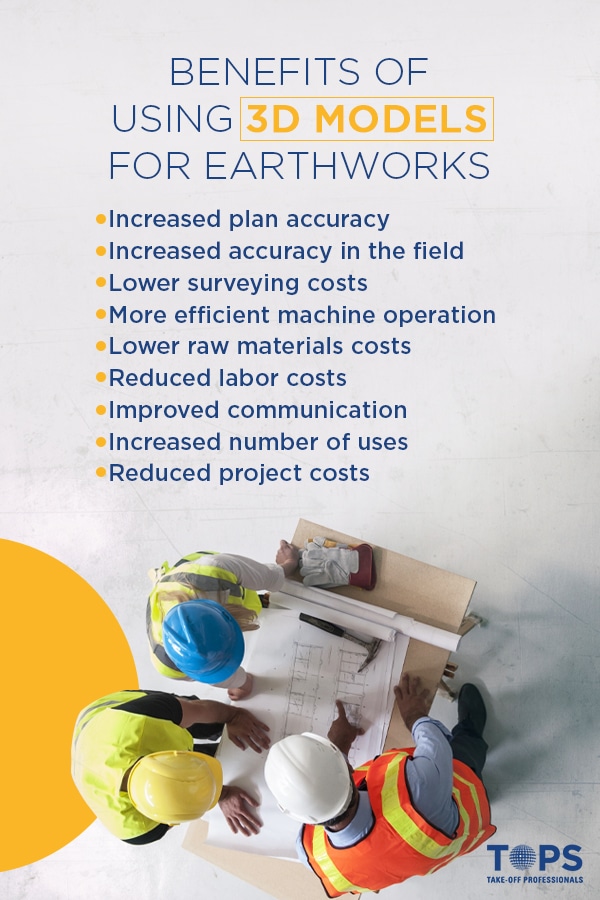

Using 3D models for earthworks and machine control can provide numerous advantages, including:

- Increased plan accuracy: Creating 3D models uncovers conflicts, inconsistencies and other issues in plans before construction begins, which reduces rework and costs.

- Increased accuracy in the field: Because the machines have the same data the surveyor does, machine operators have an easier time following project plans. Workers won’t have to rely solely on contours when navigating a worksite. The 3D replica’s surface is also built to the landscape’s actual vertical and horizontal geometry.

- Lower surveying costs: Using 3D modeling eliminates the need for ongoing grade checking, which reduces surveying costs. Having lower surveying costs can help you win more jobs and earn higher revenue over time. The additional money can also allow you to upgrade equipment and hire employees as your company expands.

- More efficient machine operation: Machinery operates more efficiently because it moves precisely according to the 3D model’s measurements. 3D modeling helps you accomplish more with your equipment in less time. The increased efficiency also reduces fuel, repair and maintenance costs.

- Lower raw materials costs: 3D modeling techniques help you hit the mark the first time around and use materials more effectively. This enhanced productivity reduces raw materials costs because you’ll need fewer supplies for each job. This benefit is sustainable and cost-effective.

- Reduced labor costs: With 3D machine control modeling, many of the machine operator’s duties are automated, which helps them work more quickly and make fewer errors — this quality increases individual worker efficiency, reducing labor costs.

- Improved communication: You can use 3D models to communicate project information in an approachable, visual way with various stakeholders. If everyone has a common understanding of the material, they’ll have a smoother time sharing ideas and suggestions.

- Increased number of uses: You can set up the data once and then use it for various purposes, including grading, utilities and hardscaping. You can also make adjustments to the information as needed for subsequent assignments.

- Reduced project costs: Using a 3D model can reduce project costs by a total of four to six percent, according to a report by the U.S. Department of Transportation’s Federal Highway Administration. In earthmoving alone, 3D models can increase efficiency by 15 to 25 percent.

The Process Behind Crafting Accurate 3D Models

To create a 3D model, you must first gather survey data. You can accomplish this by using various technologies, including LiDAR and aerial photogrammetry. The initial survey records the locations of physical features and key points, which serve as a baseline. You can then scan the area using LiDAR technology to create point cloud data models representing the physical components of a site. These point clouds combine with 3D modeling software to build the 3D representation.

When Take-Off Professionals receives the survey data files for a project, we first ensure we have all the necessary information about the job requirements and the scope of work for which our customer is responsible. We then build the 3D model based on the plans we receive. During this process, we adjust errors in the designs and take notes about potential changes.

Once we have completed the 3D model to plan, we alert the engineers to any areas of concern and propose fixes as needed. We continue to revise the model and suggest changes until every detail is correct.

To begin a 3D modeling project, we need three things:

- CAD files: You can ship us your CAD files or upload them to our site. We can use various file formats, including industry-standard formats such as .DWG and .DXF within AutoCAD, plus numerous proprietary formats. We can process any kind of CAD package from Carlson Construction, AutoCAD, Micro Station and others.

- Paper plans: We also need either physical paper plans or scans of paper plans. You can upload scanned files or send them to us on a CD. Keep in mind that it is often cheaper to ship rather than scan.

- Work order: You will also need to fill out a work order, which will include details about the project’s scope. You can submit a work order through our website.

Some of the elements that may be included in a 3D model for machine control, depending on the project, include:

- Parking lot surface

- Roads with vertical and horizontal alignment information

- Subgrade road model that extends beyond the back of the curb

- Large islands and building area curbs

- Small island curbs with grading

- Building pads, including blow-ups if requested

- Retention and sheet grading areas

- 2D linework of utilities or full 3D utility layout

- Existing conditions

- Points for the layout of objects built for the surface, such as buildings and curbs

Partner with a 3D Modeling Industry Leader

At Take-Off Professionals, we create approximately 1,000 machine control models for our clients every year. We employ a team of engineers and technical staff who are experts in building 3D models for the construction industry, and we don’t use subcontractors like many of our competitors do. We have groups working across all four major time zones in the U.S. to ensure we’re always there for our clients.

We’ve been in business for more than two decades and have established a reputation for timeliness, accuracy, attention to detail and excellent customer support. We’ve also created an exclusive platform that our clients can use to upload their files in a secure, user-friendly environment. This additional measure ensures placing a work order is fast and easy.

Learn more about how our data and modeling services can help you win more bids, reduce your costs and complete projects accurately and efficiently by contacting us today.