Many years ago, I proposed that machine control would change the surveyor’s role and made it a point to discuss this with many state surveying groups. As a rule, surveyors need to be exact. A circumstance could come up where one would have to defend their work in court. With the need for accuracy, surveyors were not happy with contractors bringing precision equipment onto a site. Some thought contractors were cutting costs by reducing survey crew trips to construction sites. However, the real reason was that a surveyor may have to go back and tell a contractor some of their work was done incorrectly. Every surveyor hates to return and re-pound stakes that got knocked over, so how do they make sure the contractor can perform great work independently?

JUMP TO SECTION

Survey Builds Data

I have been involved in lively discussions to legal debates over the production of machine control data. Regardless of the state, the answer is always the same: data built by or on behalf of a contractor is not an issue. Once that got settled the question remained, “Who should build the surface you will grade to?”

Traditional Surveying

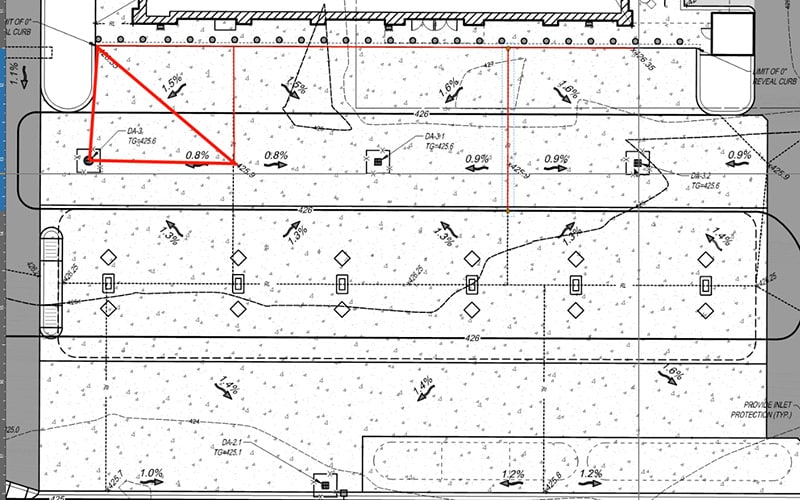

The image at the right shows what we were given in a set of plans. Points found on the plans are placed on the ground in three-dimensions with a stake. The cut/fill to the desired location was marked and the dirt was moved. When things got close, blue tops were placed with the top of the wood stake at finish. Other types have a staple in the top holding the whiskers, a good operator would “polish” the staple and get grade that

Data Models

When I started doing this work, the only frame of reference I had was how things were staked and cut in the field. Because first generation equipment was difficult to use and problematic, training and ongoing support were normal. I spent more time in the field than in the office. We would build the model and I would be in the field for days, to weeks, training crews and getting a better idea of how to leverage the data that I collected.

The knowledge I gained by working in the field allowed me to create workflows that are now commonplace. The other problem we faced was that nobody knew how to build a model, but surveyors felt they were the best option. This is a learned ability and with practice anyone can become proficient, like me for instance. I worked long and hard to figure out how a model works in the office and the field. Coupled with a good understanding of how the mouse clicks transferred to the ground, I began to connect those dots. One of the most frequently asked questions I get is who the best candidate for a data builder is. I find it easier to train a computer savvy field person than try to get a CAD expert to think in three-dimensions.

In time, more people learned how to create good data and software ran ahead to improve commands and performance. The future holds the key to 3D design and implementation of data into the field. BIM has taken the lead due to multiple trades trying to occupy the same physical space. Currently much of that design work is done with CAD technicians producing the 3D models suitable for construction.

The ability to design, (or produce 3D data from CAD and plans) is mature. We will discuss the integration of surveying and data.

Cross Training

As more contractors started to create their own files, surveyors were not building as much data but keeping busy doing the important job of positioning. It’s necessary to understand what a surveyor does, but not actually do it. Surveyors need to understand data but not necessarily know how to build surfaces. Here is what each needs to know about the other.

Somebody must make a model for the machines to work. With model in hand, it’s time to go to the field. Surveyors are critical to any job large or small. I have seen the start of too many jobs by well-meaning contractors placed in the wrong spot or incorrect elevation. The nuances of positioning are complicated, and it is the surveyor who can assist in correct site placement. The GPS lead on the jobsite needs to have some of this ability too. The most important thing is sensing an issue and when to contact survey for work to be done. I have a surveyor friend who ten years ago would build the model and give the contractor a rover with the data loaded. They would start the job and call when they needed something.

I need to be clear; office and field civil construction workers are not doing survey. We are laying out and grading to information the surveyor knows is in the right place and will perform as intended. That is the end point of data and survey working together, so how do we get there?

Data Prep

I’ll run through the process when we work with a client on a typical site job.

- We build the initial model and do the following:

- Fix obvious errors and note them.

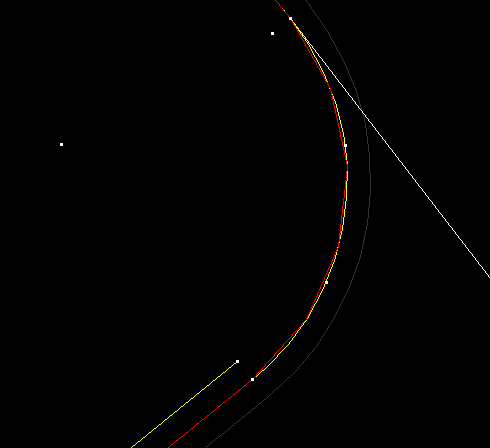

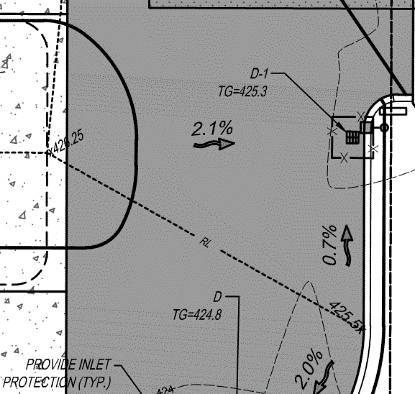

- Make grading changes to reflect proper water flow.

- Verify dates and changes to the plans to confirm current versions.

- Report these changes to the contact(s). Usually this is the contractor. As the jobs get larger, we are often asked to communicate directly with the engineers and surveyors and include the contractor in the discussions.

- Responses are received regarding questions.

- Data is updated and work continues.

The data needs to start out as a representation of the finished product. There may be changes pending but not so detailed that we must redo a lot of dirt work. This rough grade file will keep the schedule moving and let the engineers know how long we have until we run out of things to do. Hard deadlines go both ways, stakeholders need to know we are faster at moving dirt and need answers to questions.

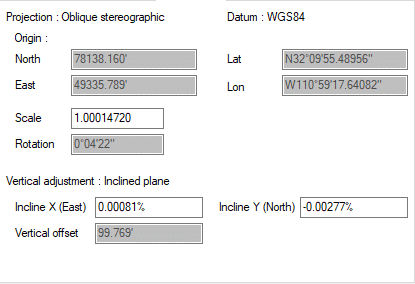

Your surveyor is invaluable at this stage, coordinate values need to be correct, the best way to know this is to bring them in early. As hired guns, we communicate with survey crews on jobs all the time. Be sure to do this early and with all jobs.

The next step in confirming data is to bring in control and verify locations and accuracy. Now that things are in the right spot and the data is close to correct, we can send the data to involved parties and gather input. Don’t expect a lot of information, everybody is busy, and most don’t have the time to review your data. It’s more of a courtesy.

Survey Functions

I have often been involved in some very detailed discussions about survey’s role on a job. I am an expert witness regarding disputes that sometimes involve surveying. I am no surveyor but have a good grasp on the practice. It takes time to be good at this and I leave it to the professionals.

The surveyor needs a plan for what they will do on your site. This prevents duplication of effort as well as ensuring it is going correctly. Here is a list of things to get right.

- Know the difference in collection times. Sometimes you can walk and click, and other times you set up the bipod and cook for a minute. This affects accuracy and a few more seconds on various point types will be rewarded.

- Perform daily check-ins. Know that when you start your day you are as correct as you were yesterday. Do this for rovers and machines.

- Share and listen. The information needs to go to the surveyors and engineers for review and comment. Again, you will not hear much, it’s just good to let them know what things look like in the field. This is a big advantage on remote jobs.

To wrap things up, learn enough about the other person’s job for better communication and efficiency. None of us can do a job that we are not trained for, but an understanding of the roles around you will go a long way in making things run smoother.