GPS MACHINE CONTROL DATA PREPARATION SERVICES

Take-off Professionals prepares a 3D model and performs related services for any type of project from commercial and school sites to subdivisions, roads and much more.

This innovative data service is available for your specific system, regardless of the manufacturer or system type: Carlson, Lieca, Topcon or Trimble. In addition, no matter what software the engineers used to create the design; Civil 3D, MicroStation or any other design software, we will provide you with the final 3D model in the proper format required for your equipment. Multi-brand fleets are easily supported.

Our knowledge and experience combined with the most innovative GPS and 3D machine control services technology available will provide laser sharp focus for your project, giving you the confidence of a job well done from beginning to end.

Learn More About How We Can Help You Earn More On Your Projects

MACHINE CONTROL DATA PREP FOR COMMERCIAL AND SCHOOL SITES

Commercial sites are a natural for machine control and precision layout. Paving must drain with proper slopes, bird bath puddles are costly to fix. We build the model on the screen as many times as it takes in order to give you a surface that will perform and make a quality job.

Here is what we provide for a typical site model:

- Parking lot surface to finish

- Larger islands and building area curbs built. Small island curbs are graded through in the model just as you do them in the field.

- Building pads and blow ups if requested

- Retention and sheet grading areas

- 2D line work of utilities

- Existing conditions

- Points for layout of items built for the surface including buildings, curbs and tops and toes of retention’s. These are just examples, ask us and we will do it for you.

These are just examples, ask us and we will do it for you.

Optional items involving extra cost:

- Full 3D utility layout for storm and sanitary. Includes points and offsets for flow-line of pipe, structure corners and rims. This is comprehensive survey layout information for utility placement.

- 3D Utility trench networks for machine control excavators.

SUBDIVISION Projects Data Preparation

Moving beyond a typical site, subdivisions have many of the same grading areas of a site with the addition of plan and profile roadways. Through our machine control services, we build the grading and pad information by starting with the Site Model description and add the following;

- Roads built by hand using plan and profile. We manually enter vertical and horizontal alignment information, build templates and process the road so it can be used for grading, paving, string-less curb and paving machines.

- Intersections are warped in by hand to insure proper drainage and a smooth transition.

- Cul-de-sac’s are done with the same attention to detail.

- Look out and walk out basement step pads can be incorporated into your model.

- We can build a sub-grade road model to extend behind the back of curb to get the curb machine in.

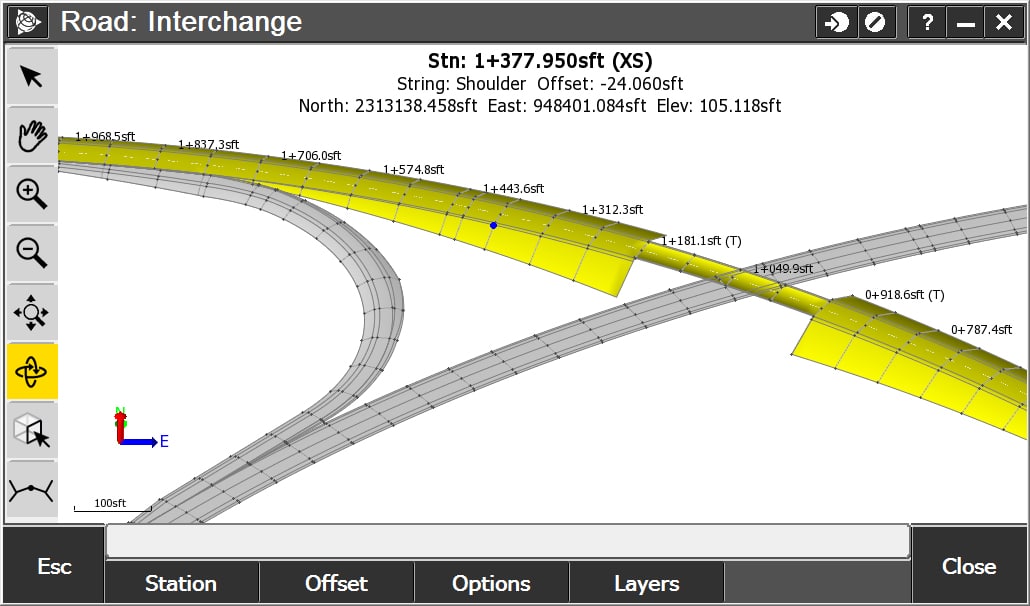

Data Prep for ROADwork And Highway Projects

Road work has two distinct processes; New Construction and Rehabilitation:

New Construction:

- All road work is done by hand. We enter alignments, build templates and make a road conforming to the engineering. Nothing is left to chance, better data means no rework.

- All our work can be used with precision GPS and robotic systems. Accuracy to 3 digits for imperial units and 4 digits for metric work.

- We can build daylight to daylight or driving lanes only per your request.

Rehabilitation:

- Mill and replace needs special attention. We are experienced with creating milling models as well as un-compacted surface files in order to minimize material and increase profits.

- Lane additions require detailed existing condition information so the new lanes do not need grinding and proper pavement depths are maintained.

What Can We Do For You?

We can work with you on a variety of levels. Our intent is to establish a relationship and make it easy for you to increase or reduce our participation to fit your needs. We offer:

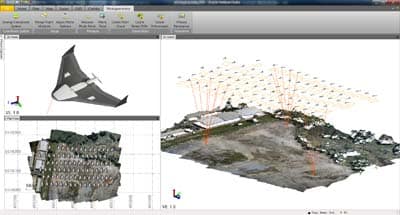

3D Machine Control Models

Our team at Take-off Professionals is here to support all of your GPS machine control modeling needs.

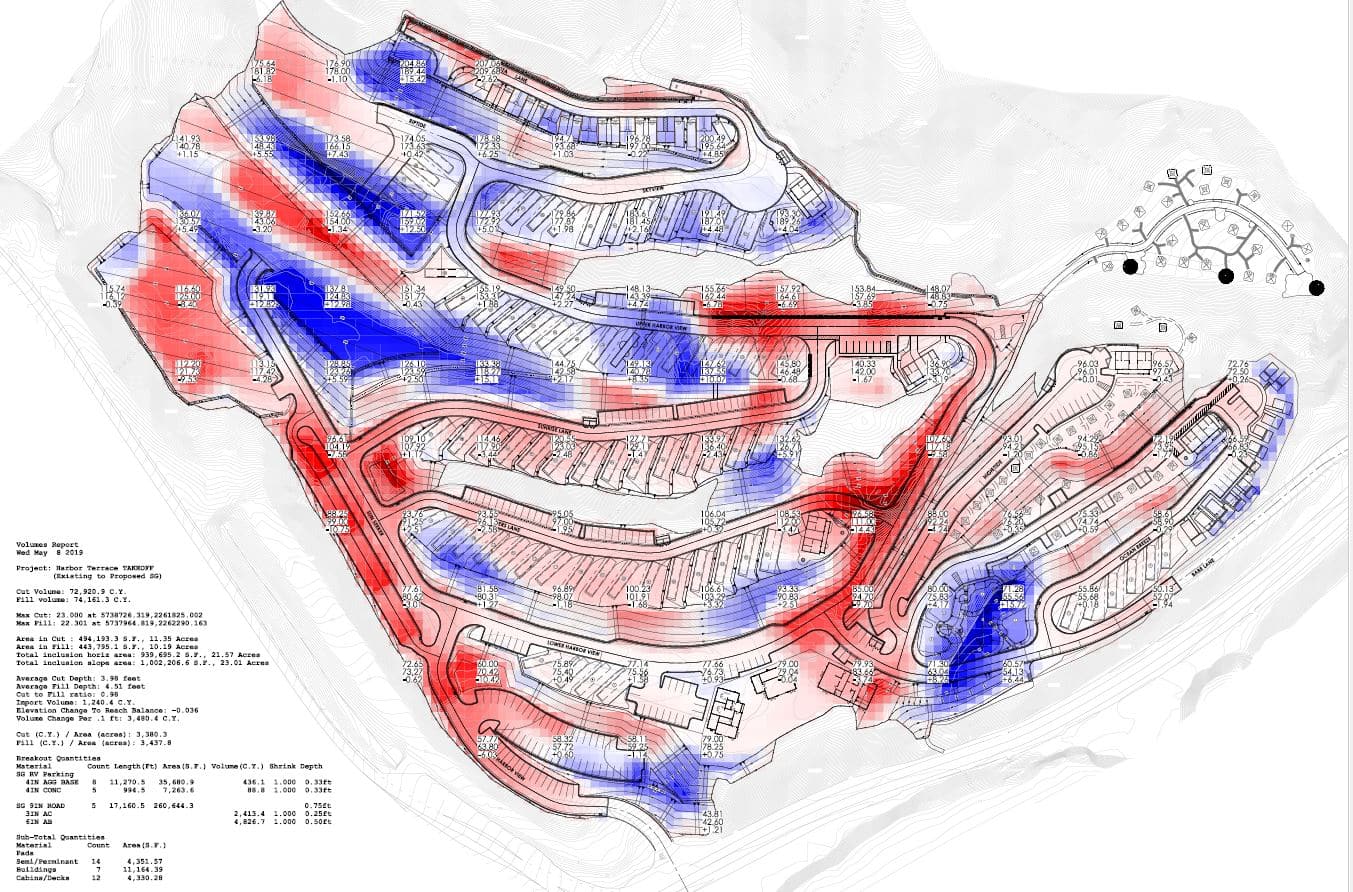

Quantity Takeoff Services

Accurate and timely quantity takeoffs will help you increase bidding accuracy and work efficiency, ultimately resulting in money saved.

Point Cloud Modeling

We are a leader in the point cloud modeling industry, providing accurate models and excellent customer service.

What our clients say