The US Survey Foot is Retiring, The International Foot is The New Survey Standard

A change came about at the beginning of the 2023 year that can have an impact on you and the survey work you do in the office and the field. The new rule:

The United States will retire the use of the US Survey Foot and unilaterally adopt the International Foot as the standard of survey measurement.

Until now, only 5 states have used the International Foot. The US Foot is a ratio and is not an exact conversion like the International. From a geodetic standpoint, this new standard will improve accuracy. The International Foot is 2 feet per million feet longer than the US Foot. This will allow you to look at the coordinates of your location instead of focusing on the size of your job.

Learn how the International Foot can affect your survey work and how to easily adopt the new standard in the field and at the office with best practices.

See the International Foot in Action

When using state plane coordinates, we are often 2-4 million feet in the coordinates of our work. If the job is produced on one unit type, then changed to the other, the job has now shifted 2 feet per million feet in both the north and east grid directions with non-affected elevations.

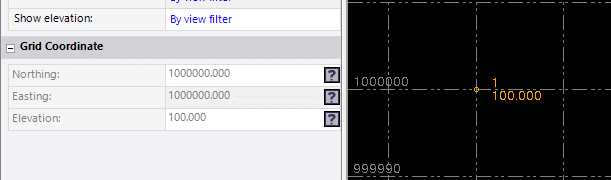

To illustrate further, here is a job started with a US Survey Feet point drawn at N1,000,000 E1,000,000.

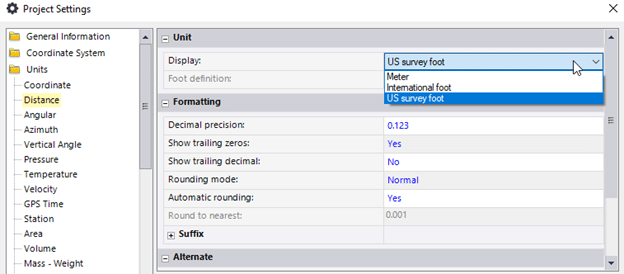

Now, let’s update the point drawn in US Survey feet by changing the units:

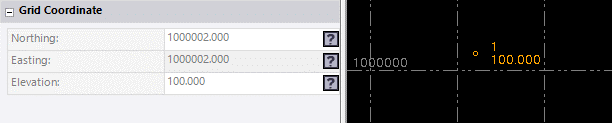

If the survey standard unit changes to the International Foot, you can see the 2-foot shift in the entire job with updated coordinate points.

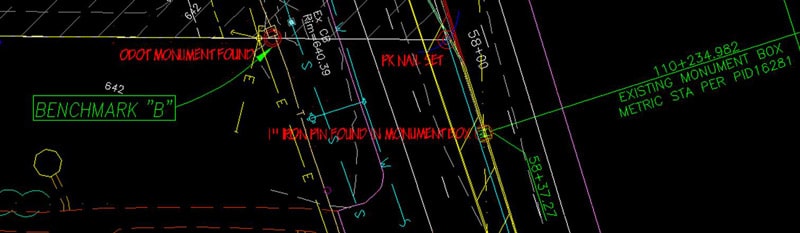

In the past when the US failed to adopt the metric system, plans were drawn in a metric that was worked on for ten years after an idea was abandoned. Similar outcomes are expected to happen with this new transition as well. Realizing the big impact that changing units can have on your jobsite, it is important to have best practices put into place so that you are set up for success and rework can be prevented.

Best Practices Moving Forward

Units should be listed within the first few pages of the job plans, so the next steps are identified. Over the next few years, while jobsites are being acclimated, here are some action items to keep your work updated and ready to transition.

- It is imperative that all parties use the same units. The job does not necessarily need to shift right away. If ALL parties are staying with US Feet, you can localize and continue.

- Do not rely on Google Earth to verify your current unit’s accuracy. It’s not a very reliable resource.

- Have control points on the job as you are building the model. It is the definitive test as to the correct units. Based on the previous example, if the control point was 1,000,000/1,000,000 you would know you were measuring in US Feet. As long as everybody stays there, you can proceed.

Problems can arise when somebody changes units either in the office or the field. So, taking the correct steps to manage the file and jobsite correctly between both places is imperative. Here are two checklists for teams in both places to reference:

In the Office

-

- Verify units by having control points before sending the job to the field.

- If you make the job in one unit type and switch to the other, make sure you export all the job files after you have shifted the job.

- Add a suffix to the job file. Now it has job name-date-units. An Example would be QuickTrip3385 010123 IFT (or USFT).

- At some point in the model-building process, send an email and receive a response including the project units.

- Software types behave differently. Some will shift coordinates and not present a warning while others will. Know your software.

- Final review needs to include the control points. Make sure the coordinates and points make it to the field for verification.

In the Field

-

- Know your units and do not change them between data collectors and machines.

- Calibrate the job with the units being used by everyone. The coordinates of your control points must match the surveyor.

- The elevation does not change if the coordinates are shifted, no need to worry about that.

- Upon starting for the day, check in to a known point for verification. This can be a control point or one you set yesterday before stopping for the day for ease of access.

If you are unsure about the new survey measurement standard or 3D modeling for machine control, reach out to TOPS and we’ll be happy to help.